Zygo

. . . a brief essay on testing telescope optics. For more involved discussion, click on link at bottom of this page.

We are regularly told by our customers, and in that we include some of our competitors who we sell optics to, that our optics are of outstanding quality. This is obviously a massive boost to our manufacturing staff and, our sales team, all of who are familiar with how we make and test our optics. One statement of fundamental importance but, very often overlooked by some manufacturers is, ‘If you can’t test it properly, you can’t make it properly’ which would appear a basic fundamental part of making optics but, it isn’t to some.

Making reasonable quality telescope optics is not that difficult, provided the investment in machinery is present. Making the highest quality optics is a different world because machines play very little part in the quality of the finished product. By far the major aspect of making good optics is in the skill of the optician and, the ability to measure accurately how the work is progressing. The word ‘measure’ is the key here.

If you carry out even the briefest internet search or visit a library you will find lots of literature on making optics, particularly paraboloids. The techniques have changed very little over the last 50 years or so but, there has been a revolution in the way these optics are measured and given specific grades of optical quality. The biggest step forward was the use of lasers fitted to interferometers, the most popular and accurate being the products Zygo corporation in the USA manufacture. http://www.zygo.com/

A Zygo interferometer, (we use a GPI http://www.zygo.com/?/met/interferometers/gpi/st/ ) is capable of checking and measuring all of the work produced in our optical labs. Accuracies in measuring which at first might seem impossible are readily and, very importantly, repeatedly made to detect errors as small as 1 /2,000 the thickness of a human hair or in numerical terms, 0.00003mm. Zygos work by producing a beam of laser light and transmitting it to the optic under test by way of a very, very accurate lens fitted to the Zygo. This is the key to the instrument’s accuracy. As the light passes through this lens, which is not coated, it enables 4% of the light to be reflected back into the Zygo. The exact optical quality of this lens is incorporated into this retained 4% of the laser light. Being of known quality, the known errors of the light can electronically in its computer, be removed. What is left, for all intents and purposes is a 4% sample of the light sent to the optic under test, with no errors present in it. As the light is reflected back from the optic under test, it passes back into the Zygo and, is compared with the previously retained 4% and then, the two are compared.

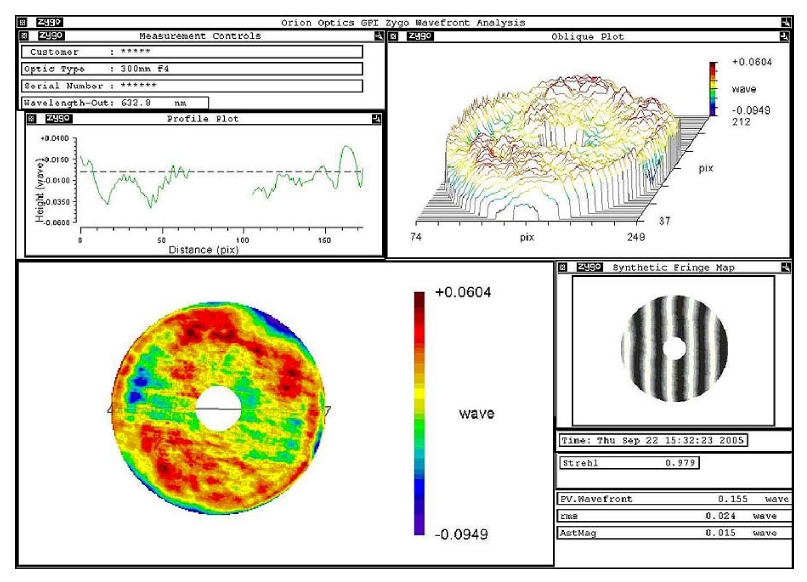

This comparison produces light and dark bands of light called fringes and these fringes show the difference from the ‘perfect’ 4% light and the light bouncing back off the work piece under test. The technician sets up the Zygo to make these fringes visible on a computer screen and then, asks the Zygo to carry out up to 100 simultaneous separate tests and measurements of these fringes to determine the deviation from what should be a perfectly set of straight lines, dark and light fringes.Typically, we carry out tests of 50 samples and then the average is worked out by the Zygo’s computer to display a set of figures which give us a very accurate representation of the optic under test. You will see a sample of the report which is then produced and then sent to all customers who are ordering optics which are higher in quality than our basic � PV wavefront requirement.

If anyone wishes to see one of our Zygos in operation, please contact us and we can arrange a visit for you. A more detailed explanation of testing and facts about optical quality can be found here.

Explanation of features on Zygo Interferometry reports

To assist customers and prospective customers in understanding a typical Zygo GPI report, we have put together descriptions of the main displayed features of the reports. Many other features are available but, due to a limited amount of space, we have decided on the current display. Please scroll down for more . . .

Before going into detail it is important to know what parameters are used in testing our optics.

- When testing paraboloids we test at the radius of curvature. This ensures that no astigmatism can be introduced into the optical path. This is a problem sometimes encountered when testing a paraboloid on a double pass set up with a perforated flat either the same size or larger than the mirror under test. Astigmatism is often introduced with this set up due to mis alignment of the optical componenets and incredible care has to be taken in correct alignment. It is totally incorrect in testing a mirror to remove astigmatism from the results electronically or otherwise on the assumption that all the measured astigmatism is in the mis-alignment and not the mirror under test or, the mirror sagging on the test bench. (If its sagging on the test bench, it will sag in your telescope.) Doing this falsifies the test as it also removes all the astigmatism from the test mirror, giving an incorrect reading. Any mirror you buy which has had astigmatism removed from the test results, is totally an incorrect value, no matter what the supplier says, its wrong, completely. Its an easy way to make a bad mirror look good by removing errors which cause a lower PV value. steer well clear.

- To test a mirror on a Zygo there is a need to slightly tilt the mirror to see fringes which are measured and also the mirror has to be perfectly focused (power). Flat surfaces are tested in a similar way but with different aspects of the test removed. Here are the features we remove to achieve a correctly designed test:

Paraboloids, spheres and telescopes . . . Piston, Tilt, Power and Coma are removed

Flats . . . Piston and Tilt only are removed only.

We will discuss any aspect of our GPI Zygo and its capabilities however, we cannot, due to technical development procedures, discuss the actual optical set up of the testing methods we use which were developed in conjunction with Zygo and the National Physical Laboratory in London.

If anyone wishes to have further details of any feature on the report or, more information on what other features are available, please feel free to email us using this link . . . john@orionoptics.co.uk