Mirror Cells

Mirror Cells

The best optics in the world can be literally ruined unless they are supported correctly in a telescope’s body. Finely hand figured surfaces, no matter how good they are, will not give their best unless the mirrors have a firm but resilient method of holding the mirror. Badly designed mirror supports (cells) are more than capable of turning the image from a 1/10PV wavefront mirror into worse than a whole wavelength of inaccuracy. How do we know this? Because we have not only seen it on many competitors telescopes that we have been asked by astronomers to check out the telescope and collimate it for them, based on the customers appraisal that the telescope was performing badly due to incorrect collimation. Badly made and/or badly adjusted cells are one of the main reasons for what appears to be a quality problem in a telescope.

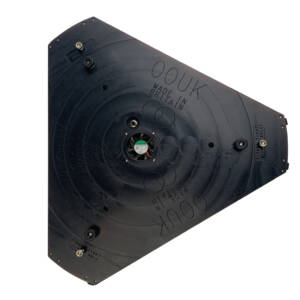

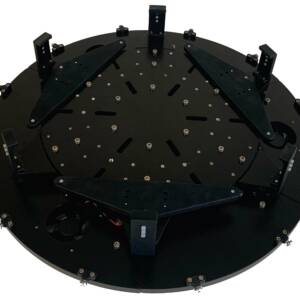

We carried out extensive tests on cells, even after our computer software designed the cells for optimum performance, we wanted to check ourselves so we tried the same mirror in different cells and, after months of trials, came up with the current design. A 9 point, nylon66 tipped suspension system which spreads the ‘load’ of the mirror as evenly as possible over those 9 points at the back of the mirror.

All of our cells are CNC machined for super accuracy but, they are all then carefully hand finished to ensure no small irregularities in the machining or threading of holes restricts movement of the parts. Anodising adds a protective layer to the aluminium which not only gives the aluminium protection against corrosion, it also produces a harder surface which reduces the risk of scratches or wear in the threaded holes. These cells will last a lifetime if looked after and cleaned very occasionally.

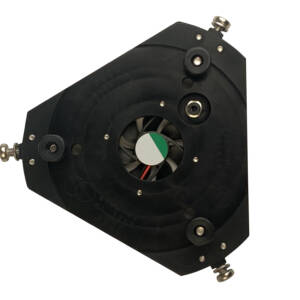

All cells have a cooling fan fitted which run off any 12 volt DC supply to reduce significantly the risk of dew and, to allow the mirror to reach observing site temperature.

Our simple and extremely robust collimation system, ensures your mirror stays exactly in the same collimated position night after night after night. The robustness of the design also gives security of constant focus. We have heard of several telescopes fitted with our cells which are observatory sited, maintaining their focus for several months, a sure sign of good design and manufacture.

Our Cells can be and have been altered to suit customers’ requirements to either fit alternate size tube or mirror thickness and diameters. If you feel we can help, get in touch, I am sure we can help.

| CNC 9 Point Mirror Cells | ||||||||||

|---|---|---|---|---|---|---|---|---|---|---|

| Description (Size) |

Part Number | Maximum Mirror Diameter | Minimum Mirror Diameter | Maximum Edge Thickness | Minimum Edge Thickness | Total Weight (Kg) | Maximum Mirror Movement | Tube Connection (multi location) | Packing Details cm / Kg (approx) | |

| 150mm | CELLCNC150 | 151mm | 151mm | 20mm | 15mm | 0.7 | 8mm | M6 | 28 x 28 x 25 – 0.77Kg | |

| 200mm | CELLCNC200 | 201mm | 191mm | 24mm | 19mm | 1.4 | 8mm | M6 | 28 x 28 x 25 – 1.54Kg | |

| 250mm | CELLCNC250 | 250mm | 240mm | 27mm | 22mm | 2.7 | 8mm | M6 | 28 x 28 x 25 – 2.97Kg | |

| 300mm | CELLCNC300 | 300mm | 290mm | 40mm | 30mm | 5.6 | 15mm | M6 | 6.16Kg | |

| 350mm | CELLCNC350 | 355mm | 343mm | 45mm | 35mm | 8.2 | 15mm | M6 | 9.02Kg | |

| 400mm | CELLCNC400 | 405mm | 394mm | 45mm | 35mm | 11.6 | 15mm | M6 | 12.76Kg | |

| 500mm | CELLCNC500 | 504mm | 498mm | 57mm | 45mm | 24.6 | 15mm | M6 | 65 x 65 x15 – 27.06Kg | |

| 600mm | CELLCNC600 | 608mm | 597mm | 57mm | 45mm | 30 | 15mm | M6 | 65 x 65 x15 – 33Kg | |

| Cooling Fan | Fansmall | for our 9 Point Mirror Cells | ||||||||

Showing all 9 results

-

CNC 9 Point Mirror Cell 250mm

£216.00 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 300mm

£302.40 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 350mm

£367.20 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 400mm

£486.00 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 500mm

£648.00 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 600mm

£810.00 excl. VAT Add to basket -

Cooling Fan

£21.60 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 150mm

£129.60 excl. VAT Add to basket -

CNC 9 Point Mirror Cell 200mm

£172.80 excl. VAT Add to basket